- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Products

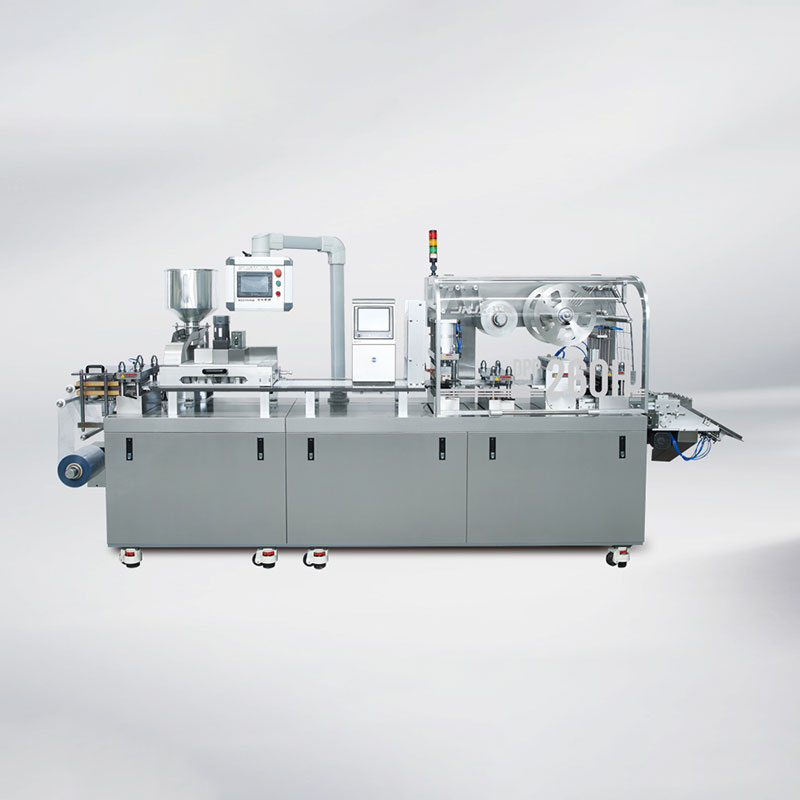

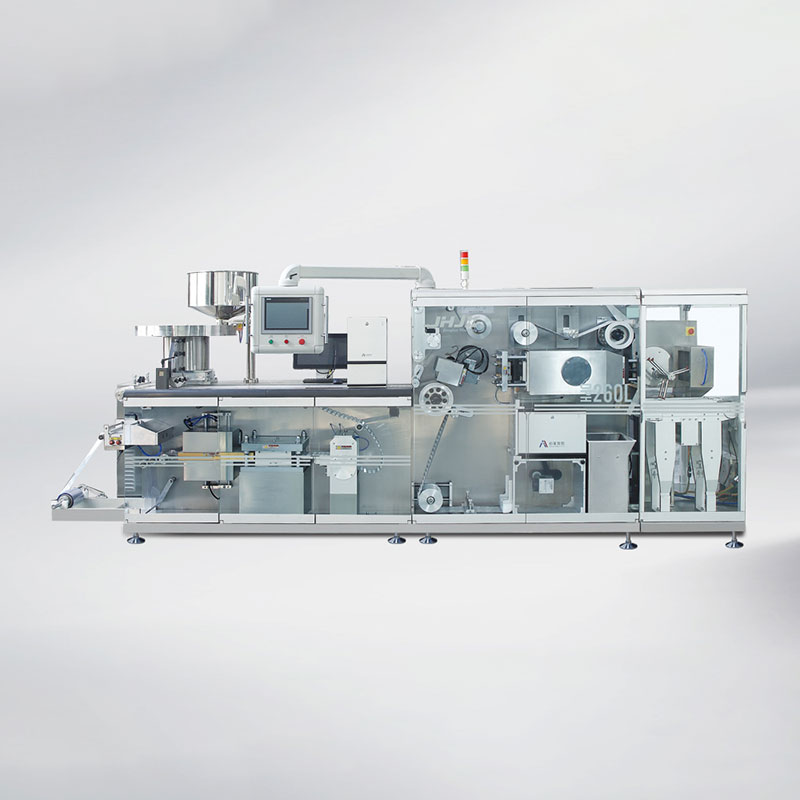

NJP-400 Fully Automatic Capsule Filling Machine

Main Features: ● Touching-Screen, PLC program control panel with LCD. ● Capsule vacuum positioned mechanism to make the capsule qualified over 99%. ● Removable powder hopper for cleaning and easy auger adjustment easy to change fills weights. ● Easy speed selection and closed capsule length...

Description

marker

Main Features:

● Touching-Screen, PLC program control panel with LCD.

● Capsule vacuum positioned mechanism to make the capsule qualified over 99%.

● Removable powder hopper for cleaning and easy auger adjustment easy to change fills weights.

● Easy speed selection and closed capsule length adjustment.

● Electrical Appliance control system approved to CE, and international standard.

● Quick and accurate change part set-up, easy to remove rotary table and ring carrier assembly.

● Fully enclosed dosing stations and rotating table for integration of the whole capsule filling plants.

● Large cam mechanism keeps the rotating table of moldtogether with the whole equipment running with balance, and completely guarantees the machine operating with highest precision and accuracy.

Main Technical Parameter:

| Model No. | NJP-400 |

| Capacity | 400 capsules/min |

| Filling type | Powder, Pallet |

| No. of Dose/holes of each mold | 3 |

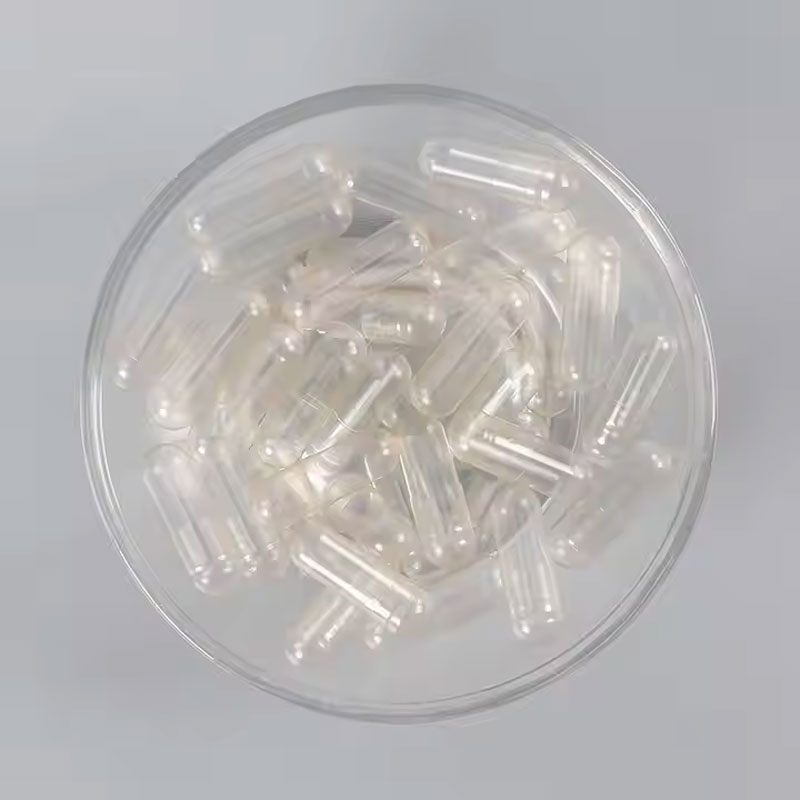

| Suitable for Capsule | 00#, 0#, 1#, 2#, 3#, 4# |

| Filling error | ±3%-±4% |

| Noise | ≤75dB(A) |

| Voltage | 380V 50Hz 3P |

| Total Power | 3.75Kw |

| Overall Weight | 600Kg |

| Gross Weight | 650Kg |

| Machine Dimension | 750mm. (L) x 680mm(W) x 1700mm(H) |

| Packing Dimension | 1600mm. (L) x 1050mm(W) x 1900mm(H) |